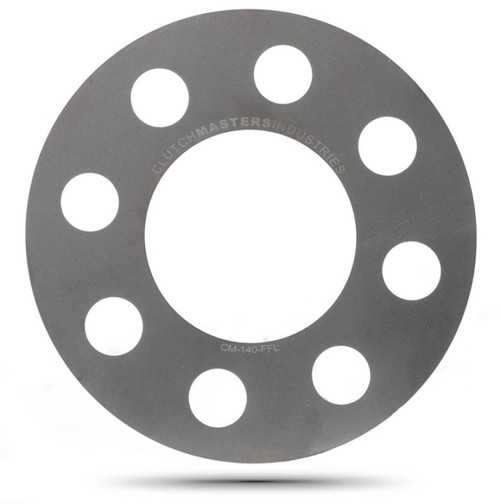

Please note product may vary from image, and some parts are special order. If delivery time is a concern please contact us for stock status before buying.

About Clutch Masters-

Historically, high performance clutches have been a compromise. While improving holding or clamping pressure, manufacturers nearly always increase pedal pressure to an uncomfortable point, especially for stop-and-go driving.

Besides drivability concerns, additional pedal pressure can adversely affect stock clutch linkage and cause premature thrust bearing wear, leading to missed shifts, damaged clutch components, and even engine damage

Today, thanks to the advancements we have been able to make through development, testing and fine tuning, Clutch Masters has been able to increase the overall holding pressure of a clutch without the increased pedal pressure and the problems that can arise from that. We have accomplished this feat by developing and implementing our Hi-Leverage™ technique on all of our pressure plates across the entire lineup of clutches we manufacture.

Excessively increased pedal pressure, which is commonplace in most high performance clutches, places an unreliable amount of pressure on the delicate crankshaft thrust bearing found in most of today's sport compact automobiles. Placing undue stress on the thrust bearing typically causes the bearing to wear prematurely or fail altogether. This failure can lead to catastrophic internal engine damage.

A clutch, simply put, is a friction device that disengages and engages the engine from the transmission to allow for transition from motionless to movement and for gear changes. For street applications a smooth transition of power is essential while still being able to transfer all the power of the engine to the transmission. As the power output of modified engines increases and demands on clutches become greater, the holding and clamping capacity of a clutch must also increase. This is where Clutch Masters' innovative engineering comes into play.

Engineering with Purpose:

Clutch Masters clutches are true high performance clutch systems and are technologically superior to anything currently on the market.

To develop a clutch with all the desired performance characteristics for intended applications is the challenge of a high performance clutch company. The Clutch Masters clutch system is unique in the industry. As you’ve just learned, we use our Hi-Leverage™ technology in all of our pressure plates, which significantly increases clamping force with no unnecessary increase in pedal pressure. Our clutch discs are specifically designed to take advantage of our pressure plates. The combination of these cutting edge technologies creates the finest clutch systems on the market.

Since we have specialized in the performance clutch industry for as long as we have, that has allowed us to research and test hundreds of different types of friction materials. From organic to ceramic, sintered iron and everything in between, we only utilize the best materials available for each intended application. By combining the optimum clamping force with the finest friction materials - each with their own unique coefficient of friction - Clutch Masters has developed a line of clutches that provide ultimate performance in virtually any severe environment.

Get the best prices and service on Clutch Masters products at Armageddon Turbo Systems (www.goturbo.net). We offer Clutch Master's full line with the best service possible.

Armageddon Turbo Systems is a company specializing in aftermarket turbocharger systems for various vehicles, particularly trucks and muscle cars. They offer complete turbocharger kits designed to significantly increase engine performance and power output.

Armageddon Turbo Systems gained prominence for their innovative approach to turbocharging, providing bolt-on solutions that allow enthusiasts to add substantial horsepower and torque to their vehicles without extensive modifications. Their kits typically include all necessary components for installation, including the turbocharger unit, intercooler, piping, fuel system upgrades, and engine management solutions.

Get the best parts and pricing on Clutch Masters today at www.goturbo.net - Armageddon Turbo Systems!